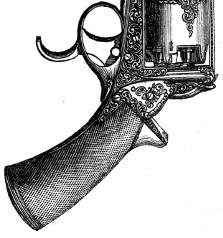

PLATE. 1.

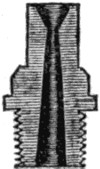

ANGULARLY LAMINATED STEEL BARRELED GUN

LAMINATED STEEL BARRELED GUN

The Project Gutenberg EBook of Gunnery in 1858, by William Greener

This eBook is for the use of anyone anywhere at no cost and with

almost no restrictions whatsoever. You may copy it, give it away or

re-use it under the terms of the Project Gutenberg License included

with this eBook or online at www.gutenberg.org

Title: Gunnery in 1858

Being a Treatise on Rifles, Cannon, and Sporting Arms

Author: William Greener

Release Date: September 23, 2013 [EBook #43799]

Language: English

Character set encoding: ISO-8859-1

*** START OF THIS PROJECT GUTENBERG EBOOK GUNNERY IN 1858 ***

Produced by Chris Curnow, Harry Lamé, Google Print and the

Online Distributed Proofreading Team at http://www.pgdp.net

(This file was produced from images generously made

available by The Internet Archive)

Please see the Transcriber’s Notes at the end of this text.

By WILLIAM GREENER, C.E.,

INVENTOR OF THE EXPANSIVE PRINCIPLE AS APPLIED IN THE MINIE AND

ENFIELD RIFLES, AND AUTHOR OF “THE GUN,” ETC. ETC.

WITH NUMEROUS ILLUSTRATIONS.

LONDON:

SMITH, ELDER AND CO., 56, CORNHILL.

1858.

(The Right of Translation is reserved.)

The urgent need for practical information on the important subject of Gunnery is evinced by the numerous patents taken out during the last few years, most of which have fallen still-born, through deficient practical science on the part of the inventors. My aim in producing this book has been to point out the errors into which many ingenious inventors have fallen, and to show how similar failures may be avoided in future, by indicating the only right road to improvement in Gunnery,—the strict observance of scientific principles in every old process and in all new inventions: for it is to the ignorance or neglect of the principles of the science that failures in Gunnery are due.

The necessity for progress in the science of Gunnery is now rendered more than ever imperative on our Government by the prodigious energy and activity of foreign Governments in providing armaments for land and sea service, the efficiency of[iv] which is ensured by adopting all the newest improvements in fire-arms. But the obstinate reluctance which all our previous Governments have shown to enter upon the, to them unwelcome, duty of investigating and experimenting on warlike inventions, necessitates strong “pressure from without;” for it may be truly said that all great improvements in Gunnery in England have been forced upon the authorities by absolute necessity, and it is still a question whether we shall profit by our recent experiences, or, as before, allow war to find us unprepared. We have, doubtless, armaments of gigantic proportions, and mammoth vessels of war, capable of discharging an ordinary ship’s cargo of shot and shell at a broadside; yet while millions have been thus expended, the improvement of the Gun, without which they would be mere masses of wood, and targets for more skilful opponents, has been neglected.

The GUN and its PROJECTILE will decide the victory in future fights. Indeed, we are even now waging war with our neighbours,—not on the battle-field or the ocean wave, but in the foundry; engineers being our generals, and founders our admirals. The present able ruler of France is actively at work, while we are but looking on: he is casting cannon the like of which have never been seen, while we are[v] spending thousands in experimenting on cast-iron and foundries; and by the time our officials have discovered the best cast-iron for heavy guns, the French batteries on sea and land will be bristling with Rifled Steel Cannon of tremendous range and endless endurance.

Woe betide this country if at the commencement of a war we should find ourselves just where we are.

The Emperor Napoleon, as is well known, is well versed, theoretically and practically, in everything relating to Gunnery. Keenly alive to the minutest points of progress he receives, investigates, and immediately adopts all inventions of value; having the ability to perceive, the sagacity to appreciate, and the liberality to reward merit wherever it is shown.

Compare his system with ours, where men are placed in official positions, and entrusted with power, not because of their ability to fulfil the duties of their office, but for very inferior and often unworthy reasons; where talent and fitness are not considered, and consequently a long routine of forms is made to serve as “a buffer” to resist the troublesome pertinacity of inventors, who are apt to disturb the serenity of reluctant or indifferent officials. And when at last a trial is granted, the invention is either rejected or approved by incompetent or prejudiced judges. While this practice prevails, England must ever[vi] be behindhand in Gunnery; for improvements in cannon and projectiles cannot be carried out by private enterprise.

In thus strongly expressing my opinion of the way in which progress is balked, I am not merely echoing a cry, but speaking from my own knowledge and experience. I am actuated by no feeling of disappointment, for my invention of “the expansive bullet” has been at last adopted here, after it had been copied in France. My object is to induce public investigation and inquiry, and to ventilate this important subject; and I trust that my antecedents, and the fulfilment of my predictions in matters of Gunnery, will give weight to this deliberate and disinterested expression of opinion.

The great favour shown by lovers of shooting to my former efforts to disseminate a better understanding of the principles of Gunnery, has been an additional stimulus to the production of the present work; and I have taken especial care that my observations should tend to the improvement of sporting arms, and the increased safety of the sportsman.

Nor has the ingenious mechanic been overlooked, for perfection of gun-manufacture must ever go hand in hand with scientific principle; and the desire to promote their combination has prompted my endeavours to elucidate the subject.

Leaving to the reader to determine how far I have succeeded in my efforts, I merely wish to add that I make no pretension to literary style, but have aimed to produce a practical work for practical men. I have drawn upon my previous works for such portions of information as were needful to give completeness to this view of the science of Gunnery, its present state, and probable future.

William Greener.

Aston New Town,

September 3rd, 1858.

| Plate | 1. | — | Laminated Steel Barrels—To face Title. | ||

| „ | 2. | — | Damascus and Fancy Steel Barrels | To face Page | 228 |

| „ | 3. | — | Stub Twist and Stub Damascus Barrels | „ | 234 |

| „ | 4. | — | Charcoal Iron and “Threepenny” Iron Barrels | „ | 241 |

| „ | 5. | — | “Twopenny” Iron and “Sham Damn” Iron Barrels | „ | 240 |

| Chapter I.—ANCIENT ARMS. | |

| PAGE. | |

| The bow—The sling—Crossbow—Field artillery of the Normans—Artillery of the ancients—Range of the crossbow and longbow—The ram of Vespasian—Guns first employed in 1327—Guns at the battle of Cressy—Cannon of 1390—Skill of English archers—Defensive armour—Portable firearms invented in 1430—Primitive hand-gun—Iron cannon recovered from the Mary Rose, wrecked in 1545—“Chambers”—Matchlock and wheel-lock—Fire-lock—Damascus gun-barrels—Birmingham guns—Spanish pistol with magazine—Percussion lock—The revolving pistol not a new invention—Colt’s revolver—Breech-loading guns | 1 |

| Chapter II.—ON GUNPOWDER. | |

| Origin of its invention—Roger Bacon’s recipe—Accidental discovery by a German monk—Gunpowder introduced by the Saracens—Its explosive and propellant properties—Composition of gunpowder—Nitre its essence—Properties of sulphur as an ingredient—Proportions and constituents of French gunpowder—Sulphur not always indispensable—Chemical principles of its composition—Component parts of different gunpowders—Source of its explosive force—Explosion at Gateshead—Variations in strength and quickness of fire—Granulation of sporting [x]gunpowder and of artillery gunpowder—Importance of suitable granulation for different firearms—Large grain powder the more effectual expellant—Fine powder dangerous—Principle of granulation—Gun-cotton—Imperfect instrument for testing gunpowder—Charcoal—Operation of making gunpowder described—“Glazing” detrimental—Utility of granulation—Fine grain powder—Dr. Ure on the projectile force of gunpowder—Dr. Hutton’s calculations and experiments—Mode of controlling the destructive force of gunpowder—Experiments to test the velocity of explosive force of different granulations—The grain should be proportioned to the length and bore of the gun—Chlorate of potassa used by the French in making gunpowder—Similar powder proposed by Mr. Parr, and condemned by Sir William Congreve—Velocity in projectile force must be gradual—Curious experiment—Operation of blasting stone, &c., with gunpowder—English sporting gunpowder—Military and naval gunpowder—Fame of English gunpowder makers | 18 |

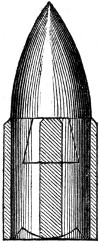

| Chapter III.—ARTILLERY. | |

| Definition of the term—Modern field gun—English artillery behind the march of science—Official obstacles to improvement—Various kinds of British artillery—Table of measurements, and range of iron ordnance—Brass guns—Their peculiar property—Firing of brass and iron guns compared—Range of brass ordnance—Paixhan guns—Traversing beds for ship guns—Ranges of Paixhan guns and howitzers—Mortars—Their uses and varieties—Monster mortar at siege of Antwerp—Table of English mortar practice—Carronades—Table of weights of guns and shot—Causes of Recoil—Guns of our ancestors—Metal required in rear of the breech—Results of Hutton’s experiments—Weight in fore-part of gun injurious—Firm base for a gun essential—Leaden bed for mortars suggested—New materials desirable for projectiles—Mr. Monk’s gun unequalled—Principle of its construction—Wilkinson’s opinion—Waste of explosive force in ordnance—The propellant force should be accelerative—This attainable by a proper granulation of powder—Government [xi]powder—Gunnery only in its infancy—Compound shot—Lead better than iron for cannon shot—Expenditure of shot at sieges of Ciudad Rodrigo and Badajos—Hutton’s experiments—The shrapnell shell—Improvements in gunnery—The Greenerian rifle—Dangerous inefficiency of English artillery—Best metal for cannon—Increased range destroys guns—Cause of mortars bursting—The Lancaster gun—English cast-iron inferior—Mallet’s monster mortar—Wrought-iron unsuited to large guns—Reason why—Shaft of the Leviathan—New method of welding iron shafts—Railway carriage axles—Nasmyth’s monster cannon—Light gun-barrels stronger than heavy ones—Brass guns inferior to cast-iron—Defect of hoop and stave gun—Form and dimensions of Mallet’s monster mortar (with engraving)—Cause of deterioration of English cast-iron—Russian cast-iron more durable, and why—Krupp’s steel gun—Laminated steel gun-barrels—Captain Dalgren’s improvements in American ordnance—Russian guns—Reinforce rings and trunnions objectionable, and why—Rifled cannon essential—Range of steel rifled cannon—Best form of gun—Professor Barlow on the strength of iron—Our artillery not constructed on scientific principles—Russian 56-pounder, English 8-inch gun, English carronade, Monck’s 56-pounder, and 10-inch gun (with cuts)—Land and sea service mortars (with cuts)—Joseph Manton’s rifle cannon—Projectiles for rifled cannon—Rifle rockets—Mr. Whitworth’s improvements in rifled guns—His polygonal projectile—Experiments with Mr. Armstrong’s field-piece—Increased range and accuracy of rifled cannon with elongated projectiles—Table of comparative range of smooth-bored and rifled cannon—Shells for rifled cannon—Spiral motion of projectiles from smooth-bored guns—Breech-loading cannon useless and unsafe | 58 |

| Chapter IV.—MANUFACTURE OF IRON FOR GUN-BARRELS. | |

| Improvement in gun barrels depends on the iron—Continental manufacturers advance while English stand still—Cheap and inferior guns of “Park-paling”—Scarcity of horse-nail [xii]stubs—Importance of iron manufacture—Great value of steel in ancient times—Iron originally made with wood charcoal—Coal coke unfit for making best iron—British iron ore inferior—Mr. Mushet on steel-iron—English workmen employed abroad—English gun-makers’ names forged in Belgium—Indian Iron and Steel Company—Indian process of making steel—Hammer-hardening recommended—Difference of “Silver steel” and “Twist steel”—Method of making laminated steel—It is spoilt by over-twisting—Watering of Damascus barrels—Proportions of carbon in steel and iron—Damascus barrels often plated—Modern method of making Damascus iron (with cuts)—Objection to wire-twist iron—Figured barrels—Damascus barrels made in Belgium—Damascus iron inferior in strength—Use of old horse-shoe nails for gun-barrels—Stub iron alone insufficient—Prejudices of provincial gun-makers—Mixture of steel and stub iron—Importance of welding on an air furnace—Proportions of steel and stub iron—Efficacy of hammer-hardening and reworking iron—Improvements in superior iron owing to gun-makers—Explosions of steam-boilers owing to neglect or bad construction—Boiler iron improveable—Steel-Damascus barrel iron—Manufacture of “charcoal iron”—Imitation of “smoke brown”—Gains from using inferior iron—Frauds in barrel making—Advice of Edward Davies in 1619—“Threepenny skelp iron”—“Wednesbury skelp”—Test of a safe gun—“Sham damn skelp”—Base guns made to sell—Their injurious effect on the gun-making trade—“Swaff-iron forging.” | 146 |

| Chapter V.—GUN-MAKING. | |

| Barrel welding—Birmingham welders—Different twists of metal (illustrated with cuts)—Process of welding—Hammer-hardening—Belgium welders—Mode of plating barrels—Belgium method (with cut)—Profits of fraud—Qualifications of a good gun-barrel maker—Processes of boring and grinding—Proper inclination of double barrels—Elevation of barrels should be proportionate to charge and distance—Brazing of barrels detrimental—Mr. Wilkinson’s opinion—Solid ribs requisite—Advantage of [xiii]the patent breech—Best shape of breech (with cut)—Gun locks—Their scientific construction—The Barside lock—Messrs. Braziers’ locks—The stock, fittings, &c.—Recipe for staining steel barrels—Birmingham method of browning—Belgian method—Varieties of iron for best barrels—Laminated steel barrels never known to burst—Base imitations of laminated steel—Cost of laminated steel barrels—Author’s method of laminating—Stub Damascus passed off for steel—Birmingham guns—Practice of forging names of eminent makers—Author’s offer—Improved metal for axles—Author’s imitation Damascus (with plate)—Joseph Manton’s merits—Prize medals awarded to author—Advantages of Birmingham for gun making—“London-made guns”—Foreign imitations of English guns—Periodical exhibition of guns recommended—Steel-twist and stub Damascus (with plate)—Barrels of charcoal iron—Inferior guns—Cost of skelp-iron guns—Cost of “sham damn iron” guns—Sham guns (with plate)—Cost of “park-paling” guns | 185 |

| Chapter VI.—THE PROOF OF GUN BARRELS. | |

| Proof-house of Gun-maker’s Company—Proof Acts of 1813 and 1815—Provisions of Gun Barrel Proof Act of 1855—Penal clauses—Schedule B—Proof marks—Scale of charges for Proof—Mode of proving (with cut)—Number of barrels proved in 1857 | 243 |

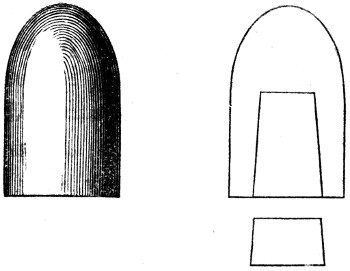

| Chapter VII.—THE SCIENCE OF GUNNERY. | |

| New principle—Improved rifles—Useless inventions—Scientific principles of gunnery: 1. The explosive power and its velocity. 2. The retarding agents. 3. Construction of the tube. 4. Form of projectile—Robins’s theory—Hutton’s experiments—Suitable velocity the germ of the science—Author’s experiments and their results—Penetrating power of bullets—Resistance of the atmosphere—Friction detrimental—Construction of the tube—The Cylindro-conoidal form best suited for projectiles—Jacob’s and Whitworth’s bullets—Lengthened projectiles tend to burst the barrel—Amount of heat needful to explode [xiv]gunpowder—Advantage of unglazed powder—Percussion powder—Best form of nipple (with cuts)—Propellant velocity the grand desideratum—Why short guns shoot better than long ones—True science of gunnery—Cause of guns bursting—Mr. Blaine’s difference of opinion with the author on explosive force—Shooting powers of different gun barrels—Tables of strength and pressure—Colonel Hawker’s axiom—Mr. Daniel’s remarks on shot—Duck and swivel guns—The wire cartridge—Bell-muzzle guns—Mr. Blaine on long barrels—The just medium—Belgium guns will not stand English proof—Cause of their inferiority—French gun-makers behind the age—Author’s notes on the “Specimens by French Gun-makers at the Paris Exhibition”—On recoil in shooting—Causes and experiments—Mode of determining the size of shot suited to the bore of gun—Mr. Prince’s double gun | 257 |

| Chapter VIII.—THE FRENCH “CRUTCH,” OR BREECH-LOADING SHOT GUN. | |

| Breech-loading fire-arms unsafe and inferior—Objections specified—Trial of breech-loading against muzzle-loading guns—Danger from using breech-loaders—Excessive recoil | 329 |

| Chapter IX.—THE RIFLE. | |

| Robins’s prediction verified—Barrels first rifled at Vienna in 1498—Earliest elongated bullets—Captain Delvigne’s bullet—The author’s expansive bullet—His memorial to the Board of Ordnance—Report of its trial by the 60th Rifles in 1836—Decision of the Board of Ordnance—Progress of the author’s invention—Captain Delvigne’s patent of 1842—Captain Minié’s bullet of 1847—Unsuccessful attempts of author to have his claim to the invention of the expansive bullet recognised by Government—Secret report of Select Committee on his invention—His priority admitted by the Emperor Napoleon—The British Government award the author 1,000l. for his invention—Principle of the expansive rifle bullet—Projectiles may be [xv]lengthened with increase of range—Action of the expansive bullet—Defects of the Minié bullet—Colonel Hay’s improvement—Author’s experiments, and their result—Spiral curve of the rifle barrel—Failure of the “Pritchett bullet”—Captain Tamissier’s theory—Minié and Greenerian bullet contrasted (with cuts)—Author’s improvement of 1852 (with cut)—General Jacob’s bullet (with cuts)—Remarks of Lieutenant Symons—The Whitworth rifle—Its defects—Report of trial of the Whitworth and Enfield rifles—Author’s comments thereon (with cuts)—Importance of safety from accident—The expansive bullet can be made superior to the Whitworth—Fallacy of experiments—Comparative cost of ammunition for the Whitworth and Enfield rifles—Defective cartridges—Hints to obviate defects—Vital principle of elongated projectiles—A hollow bullet proposed, its defects—The Swiss bullet—Doubtful utility of the deepening groove—Government rifle, with sword bayonet—Double rifles—Hints on rifle shooting—Author’s expanding screw bands—Mr. Prince’s breech-loading carbine—Revolving rifles—French school of rifle practice—English school of rifle shooting at Hythe—Double rifled carbines recommended—Revolvers costly and fragile—Lieutenant Kerr’s opinion of the Enfield or Greener’s carbine—Government pistol and carbine—Efficient arms of the Irregular Cavalry of India—First use of greased cartridges in India—The three-grooved and poly-grooved rifle (with cut)—Spherical bullets indispensable to smooth bored muskets—Length and bore of military rifle—Elliptical bored rifle—Mr. Lancaster’s bullet superseded by the Greenerian bullet—Report of committee on Lancaster’s rifle—The oval bore not a new invention—Inferiority of the two-grooved or Brunswick rifle—The Prussian needle gun—Enfield rifles made for France, Russia, and other states of Europe—Trials of Whitworth and Enfield rifles—Unsatisfactory results of the Whitworth rifle | 338 |

| Chapter X.—REVOLVING PISTOLS. | |

| Immense demand for them—Their value—Best manufacturers—Colonel Colt’s repeating pistol described—Its double action discussed—Machine-made pistols not equal to [xvi]hand-made—Dean and Adams’s revolver described—Its improvements on Colt’s—Tranter’s double trigger revolver—His lubricating bullet and other improvements—Webley’s revolver—Comparison of self-acting and cocking-lock pistols—Tendency of revolvers to foul—Lieut. Symons’s opinion—Other defects to be overcome—Author’s preference for double-barrelled fire-arms in warfare | 413 |

| Chapter XI.—ENFIELD RIFLES. | |

| The name explained, and weapon described—Its origin—Author’s share in its construction—American machinery for gun-making—Extent and products of the Enfield manufactory | 429 |

| Chapter XII.—THE HARPOON-GUN FOR WHALE-SHOOTING. | 432 |

| Chapter XIII.—SHOT, CAPS, AND WADDING. | 435 |

RIFLES, CANNON,

AND

SPORTING ARMS.

From the earliest ages of the world, the jealousies and bickerings of mankind have been fruitful causes of war. Sometimes, perhaps, justified by political reasons; at others, it may be, arising solely from a desire, on the part of ambitious chiefs, to extend their territories by multiplying their conquests; while, in too many cases, the struggle for religious ascendancy has led to the most sanguinary and cruel battles.

War has been considered as a science from the most remote ages, and the ingenuity of the talented has successively been taxed to render it as perfect as possible. It is true—

but these soon gave place to others, more calculated to decide unequal, and often protracted, conflicts.

Arms, in a general sense, include all kinds of weapons, both offensive and defensive; and amongst the earliest may be classed the bow and arrow, as it gave facilities to man to capture the wild animals for food, probably before their use was required for the purposes of war. The bow and the sling were the first means invented, and next only to the human arm for projecting bodies with an offensive aim: the great principle which, to the present day, reigns unrivalled, developing the ruling passion of man to injure, while remaining himself in comparative safety,—“self-preservation” being “the first law of nature.”

To the bow and sling were soon added spears, swords, axes, and javelins, all of which appear to have been used by the Jews. David destroyed Goliath with a stone from the brook. The invention of the sling is attributed, by ancient writers, to the Phœnicians, or the inhabitants of the Balearic Islands. The great fame that these islanders obtained arose from their assiduity in its use; their children were not allowed to eat until they struck their food from the top of a pole with a stone from a sling. From the accounts left us (probably fabulous), it appears that the immense force with which a stone could be projected, can only be exceeded by modern gunnery. Even at that early age, leaden balls were in use as projectiles; though we cannot put much faith in Seneca’s account of the velocity being so great as frequently to melt the lead. The use of the sling continued over a long period of time, even as late as the Huguenot war in 1572.

The bow is of equal, if not greater, antiquity. The first account we find of it is in Genesis, 21st chapter and 20th verse, where the Lawgiver, speaking of Ishmael, says, “And God was with the lad, and he grew and dwelt in the wilderness, and became an archer.” The arms of the ancient Greeks and Persians were such as we have described, with the addition of chariots armed with scythes, in which the chiefs sometimes fought; though their main dependence was upon their heavy-armed infantry. Elephants were afterwards used as adjuncts in their military operations, but their use does not appear to have been very great or very permanent.

The Romans were armed much in the same manner as the Greeks, with a slight difference in the form of their weapons; and the arms of the early Saxons were similar; those of the Normans were only altered in their construction, except that to them appears to be awarded the invention of the cross-bow, an instrument which afterwards became of great repute in England and elsewhere. It has also been asserted, that the Normans were the first to introduce a species of field artillery, from which stones and darts were thrown, and arrows, headed with combustible matter, for firing towns and shipping.

The artillery-proper of the ancients, as the engines for projecting masses of stone and such like materials may be termed, reached to wonderful perfection; and the velocity with which missiles of every description could be thrown from them, attest the skill and ingenuity exercised in their construction: indeed it is[4] quite evident they are only excelled by the more portable, and simply constructed, artillery of our own day.

The great artillerist of the Sicilians, Archimedes, seems to have made some of the most powerful engines; but he, considering any attention to mechanics as beneath the philosopher, has not left us an account of any one of them.

It is said of the cross-bow that a quarrel could be projected from them 200 yards, so that we may imagine the force with which one of these lumps of iron would strike even the strongest armour,—as the velocity, to range that distance, would not be far short of 900 or 1,000 feet per second; nearly equal to the effect of a ball from one of our old imperfectly constructed muskets.

We are told incredible stories of the abilities of some of our bygone archers. Should it be true, as stated, that an arrow could be shot nearly 700 yards, we can easily conceive the immense velocity with which it must have left the bow; this range being quite equal, if not superior, to that of the late unimproved rifles. Though we must bear in mind, that the peculiar shape of the arrow fits it to cut the atmosphere with less resistance then the half sphere of a bullet; and hence one reason of its obtaining an extensive range. There is a story told of the famous Robin Hood, and Little John, “who could shoot an arrow a measured mile.” We suppose the mile was the reverse of an Irish one, or they had the advantage of a precious stiff gale of wind. Historians[5] sometimes “draw the long-bow” as well as archers. Many statements have descended to us of the power of the battering rams of old; but we have a much more ready method of blowing open gates by a single bag of gunpowder; and a 68 lb. shot has all the force that could be given even to that famous ram of Vespasian, “the length whereof was only fifty cubits, which came not up to the size of many of the Grecian rams, had a head as thick as ten men, and twenty-five horns, each of which was as thick as one man, and placed a cubit distance from the rest; the weight, as was customary, rested on the hinder part, and was no less than 1,500 talents; when it was removed, without being taken to pieces, 150 yoke of oxen, or 300 pairs of horses and mules, laboured in drawing it, and 1,500 men employed their utmost strength in forcing it against the walls.”

With these remarks we shall proceed to introduce the invention of Gunnery.

Barbour, in his life of Bruce, informs us that guns were first employed by the English at the battle of Werewater, which was fought in 1327, about forty years after the death of Friar Bacon; and there is no doubt that four guns were used at the battle of Cressy, fought in 1346, when they were supposed to have been quite unknown to the French, and tended to obtain for British arms the victory. Froissart gives an excellent representation of a cannon and cannoneers, in 1390, a cut of which we give in the following page.

The use of guns in warfare is, therefore, comparatively of modern date, and the early specimens which[6] are still extant, of which we have drawings and descriptions, must have been of very little service compared with those of the present day. The English musqueteer was formerly a most encumbered soldier. “He had, besides the unwieldy weapon itself, his coarse powder for loading in a flask, his fine powder for priming in a touch-box, his bullets in a leathern bag, with strings to draw to get at them, whilst in his hand were his musket-rest and his burning match; and when he had discharged his piece, he had to draw his sword in order to defend himself. Hence it became a question, and was so for a long time, whether the bow did not deserve a preference over the musket.”[1]

[1] Grose’s “Military Antiquities.”

The mention of the long-bow is frequent in English history, and its use contributed, in no mean degree, to many important victories. Perhaps it might be[7] that our forefathers were more skilful in the use of their weapons than their adversaries.

In our wars in France, in the reign of Edward III., thousands suffered by the English archery; and the brilliant success which attended them was, at that time, attributed to their “superior skill, combined with the valour of the Black Prince.” So highly was this practice esteemed, that many statutes were enacted in successive reigns to encourage or enforce it.

Archery furnished matter for oratorical display, both in the senate and the pulpit; the palace and the cottage alike bore testimony to the great importance which was attached to the art; and it was at once the study and pastime of the whole nation. Thus, long after the introduction of fire-arms, the long-bow was held in great esteem; and it is no wonder that this favourite instrument should have been reluctantly relinquished, after obtaining such universal popularity, and becoming so intimately connected with many national and important events. It is now superseded by the gun, a more potent and destructive engine. The bow, so much valued, has vanished from our ranks by slow gradations, to make way for the musket; and the quivers of cloth-yard shafts have been supplanted by bristling bayonets. These things are now practically unknown as military weapons, though they contended for superiority with fire-arms during two centuries.

At this period, and for a long time previously, more attention was paid to the fabrication of defensive armour, than to the invention of weapons of[8] an offensive character; hence the perfection that was attained in the manufacture of mail, of every variety, during the fourteenth and fifteenth centuries. The splendid manner in which some of the chivalrous knights of that age chose to have their armour constructed and ornamented sometimes proved fatal to themselves. Froissart relates that Raymond, nephew to Pope Clement, was taken prisoner, and put to death by his captors, in order that they might become possessed of his magnificent armour. Those gorgeous and costly fabrications were likewise doomed to give place to the advancing knowledge and skill of succeeding generations; being now only known as matters of history, and regarded as valuable curiosities. So late, however, as the latter part of the sixteenth century, armour formed part of the military equipment; and the French cavalry, called carabins, are described as having the cuirass sloped off the right shoulder, that they might the more readily couch their cheeks to take aim, while their bridle arms were protected by an elbow gauntlet.

The invention of portable fire-arms is awarded to the Italians by Sir Samuel Meyrick, and, in a memoir in the Archæologia of the Society of Antiquarians, he has named the year 1430 as the precise period of their introduction.

We have already stated that cannon, or heavy ordnance, was in use in the English army in 1327, more than a century before that time. It is not improbable, however, that the Italians were the originators of small fire-arms, for they had for many[9] years been celebrated as skilful in the art of making armour—Milanese armour being considered the most valuable, and it is natural that their attention should be directed to the construction of offensive weapons of a different description.

The invention of the portable fire-arm, in its primitive state, was one of extreme simplicity; the gun consisting merely of a tube fixed to a straight stock of wood, about three feet in length, furnished with trunnions, cascable, and touch-hole: the latter was, in the first instance, at the top, like a large cannon, but was afterwards altered to the side where a small pan was placed to hold the priming, and lessen the liability of its being blown away by the wind. This contrivance was the first step to the gun-lock.

Before the adoption of the match-lock by the English, cannon, as I have before shown, had been in use, though they were of a clumsy description.

To the indefatigable exertions of Mr. Dean, we are indebted for the recovery of several brass and iron guns, belonging to the “Mary Rose,”—a vessel of war, wrecked in the reign of Henry VIII. of England, and Francis I. of France, in 1545: “while standing along the coast, during a distant firing from the French fleet, under Admiral Annebout, she was overpowered by the weight of her ordnance, and sunk, together with her commander and crew of 600 men.” One of these iron guns is in an excellent state of preservation, considering it to have been immersed above 300 years. The cut on next page will convey, together with the following description, a faint idea[10] of its unwieldy and inefficient construction. It is composed of a tube of iron, whose joint or overlap is as its length; upon this is a succession of iron hoops, composed of iron three inches square, being in fact immense rings; these appear to have been driven on while red hot, and thus, by their contraction, forming a much stronger gun, when combined with the interior tube, than the generality of accounts given of ancient guns would lead us to expect. It will be perceived, that to describe it as “composed of iron bars hooped together,” is not correct. We may also mention, that if parties describing guns of this primitive manufacture will observe accurately, they will find that this is the general method by which they have been fabricated. They all appear to have been loaded by removing a breech part, or chamber, inserting the charge, replacing the chamber, and securing it by wedging it behind; as will be seen on a close inspection. No means of raising or depressing the muzzle appear available;[11] the barrel or gun being sunk in a large block of timber, and secured there by bolts, as a musket barrel is secured in its stock; while a large piece of iron, or wood, was inserted perpendicularly into the deck to prevent the recoil. The advantage of “chambers” was perfectly understood even at this early period; they were apparently slightly conical, with a spherical bottom. It is no mean evidence of ancient skill, and knowledge of gunnery and mechanics combined, to state, that only a few years ago, a gunmaker of some celebrity, constructed a number of rifles and pistols to load at the breech, on the very same principle adopted in this gun 312 years ago. Strange, evidence from “the vasty deep” to show “there is nothing new under the sun.”

During the sixteenth century, fire-arms of every description then in use underwent a variety of alterations and improvements; each change bringing with it a change of name, which would neither be profitable or interesting to enumerate here; our object being to trace out the advances which have been made in the manufacture of fire-arms since their general adoption as weapons of war, or auxiliaries to the sports of the field.

When first introduced into England, the hand-gun, as it was termed, had already received a slight improvement, in having a covering for the pan which contained the priming, and a sight on the breech, to assist in giving greater certainty to the aim; it remained thus until the trigger of the cross-bow suggested a contrivance to convey, with equal certainty[12] and greater rapidity, the burning match to the pan.

The difficulty of using an instrument thus objectionably constructed, was in some degree obviated by the Germans; who, together with the Italians, were no doubt at this early period the principal manufacturers; they effected this, to a certain degree, by giving the stocks a crooked form, so that the breech could, with more ease, be brought to the level of the eye; this was, however, only an alteration of form, without involving any principle or leading feature of mechanical invention. Succeeding the match-lock, in the progress of improvement, came the “pyrites wheel-lock,” an invention then looked upon as exceedingly curious and ingenious; this also is ascribed to the Italians, and one of the first occasions of its being used, is said to have been when Pope Leo X. and the Emperor Charles V. confederated against France. Whether the Italians are fairly entitled to the merit of this invention is, however, a matter of doubt, as it is well known that wheel-locks were for a long period manufactured in Germany.

The “snaphaunce” or fire-lock, is distinctly stated by Grose to be of Dutch origin,—hence the name. It was introduced into England in the reign of Charles II., though its general adoption is stated not to have taken place until the reign of William III., about 1692. Since that period, until the present, their use has been general in all the armies of Europe. How strange it seems that the Chinese and other Asiatics should have only the match-lock to the present day,[13] while there can be no question that they used gunpowder some centuries before its introduction into our portion of the habitable globe!

The Syrians were formerly celebrated for their skill in the working of iron. Damascus gun-barrels were not to be obtained, at certain periods, at a price less than their weight in silver. The elaborate mixtures in their barrels, swords, and other weapons, entitle them justly to the honour of being the best of iron workers, as we shall hereafter have occasion to show; and the splendour displayed in their inlaying attests their taste and ability: but as mechanicians, formers of complex machinery, they never reached mediocrity. Turkey and Greece, as well as other countries which were renowned as having been, in days of yore, nurseries of the arts, but which have, in later times, degenerated into a condition little better than semi-barbarous, were remarkable for the great labour and pains which they bestowed upon the exterior ornaments of their firearms; but they never succeeded in improving the machinery of the lock in the slightest degree.

Although it was not until the latter part of the seventeenth, or the beginning of the eighteenth century, that gun manufactories were established in this kingdom, yet we have attained to a degree of perfection and excellence unequalled by any other nation in the world. Birmingham is the emporium of the world for guns, from the most inferior—the “park paling,” so called, of the slave-trade, with which ships might yet be freighted at the cost of eight shillings and sixpence each—up to the elaborately-finished gun of the peer. Most of the[14] alterations which have been made in gun-locks in England, have been with a view to simplify the machinery, and obtain the greatest quickness in firing: much complication has been discarded; a thorough conviction having seated itself in the minds of Englishmen, that to attain perfection, simplicity must be combined.

Many splendid emanations of genius are left to us, consisting of complex mechanism for gunnery. The most perfect we have ever seen, is a pistol made in Spain about the end of the seventeenth century. By moving a lever towards the butt-end, while the muzzle is depressed, the lock is primed, half-cocked, and the hammer shut down; return the lever, the powder is in the breech, and the ball before it. We have seen it fire twenty-six shots without a failure, and with one supply of ammunition. The magazine was in two tubes in the stock. The chance of blowing up was thought remote; but it eventually blew up. In short, it would be strictly advantageous to inventors in gunnery, to be sure that there has been no previous invention combining their principle as well as their arrangements.

The mine of complex inventions was exhausted during the last century; and the greatest benefactor to the science of gunnery will be he, who, blowing away the cobwebs of mystery, renders its principles as clear as the silvered glass. Nothing now remains of the beautiful machinery of the flint lock; the fancy cock and hammers have given place to a “simple” hammer, striking on a copper thimble, covering a steel pivot. What would the old lock-filers[15] say to this, if they could return and see their handiwork consigned to the scrap-box as old iron?

To those curious in the progress of invention as it relates to gunnery, it would be highly interesting to visit the “Musée d’Artillerie” of Paris, and there to study the classified selections in the possession of the French Government. Among other specimens equally interesting, he will find revolving pistols, revolving rifles, and swords and revolving pistols combined in one; and these produced in the early part of the seventeenth century. The revolving pistol did not therefore originate with the present generation; and however universally we may use the “Colt,” “Adams,” or “Tranter,” neither can lay the slightest claim to originality. In that museum will be found four, five, and six charge chambers; and though in all there is certainly an absence of movement in the chamber, produced by the cocking of the lock, yet several present the appearance of having formerly had some mechanical adjunct for revolving the chamber: this, though well adapted to the present percussion system, must certainly have been troublesome to manage in the old flint lock; for when the first barrel was discharged, the priming of the other barrels would be lost during the revolution of the chamber.

A great improvement was, however, soon introduced; a hammer and pan were attached to each division of the chamber, and each being already primed, presented itself in rotation in the face of the flint. The gun or pistol was by these protuberances rendered clumsy and cumbersome, and thus fell, no doubt, into disuse;[16] but every real mechanic must see on investigating the subject, that the principle was as perfect as that which is now in use. Mr. Colt had considerable difficulty in securing a patent for his revolver. The right of patent hinged on this simple question: did he, or did he not, first introduce a crank or lever for revolving the chambers during the cocking of the lock? After an expensive trial it was decided that he did introduce it; though doubts are still entertained whether there is not now extant a pistol having the same crank movement as that found in the “Colt” and other revolvers. At all events the invention of revolving pistols originated with our progenitors, more than 200 years ago, though their re-introduction is unquestionably due to Mr. Colt; and the “old broth warmed up” has no doubt proved more nutritious than the original concoction. In the Paris museum, a number of breech-loading guns are to be seen; I think more than sixty varieties. Many of them are highly ingenious, displaying great mechanical knowledge and working skill, and the whole, kept in splendid order, cannot fail to command attention.

Well had it been if the many hundred inventors in England and elsewhere had studied, and made themselves intimately acquainted with the productions there to be seen in such abundance. Monuments they are of mis-spent skill and labour; samples of the almost hopeless task of fabricating complicated machinery which shall resist the action of explosive gases at high pressure. An experiment extending over two hundred years, but unattended with success, notwithstanding all the skill and ingenuity brought to[17] bear upon it, is, we think, sufficient to prove that breech-loading guns cannot be made sufficiently durable to yield any reasonable return for the extra expense and trouble attending their fabrication. Nevertheless, our “would-be mechanics hope against hope;” and to such we would, in conclusion, tender a word of advice. Before spending your money, make acquaintance (and an intimate one is necessary) with all that has been done before, and if in your own production you find principles which have been untouched by any previous invention, and untainted by any of the previous causes of failure, then patent your invention, and make a fortune—if you can.

Great mechanical skill, and even scientific principles, are to be found in some of the earliest productions after the invention of fire-arms; and thus is established the important fact, that want of experience was the chief drawback under which they laboured: one elaborate machine being unequal to their requirements was succeeded by another; and yet, with all these examples patent to us, we still fruitlessly fall back on exhausted principles.

A more intimate knowledge of what our predecessors have accomplished would be a great boon to our race. Foreign nations, but especially France, have provided for this by their museums; and we want here a museum of progression, an epitome of the mind of the present age, and which, continued to future generations, would leave to no man the fruitless toil of hauling in an endless rope.

Gunpowder being the base on which the superstructure of this treatise is to be raised, the history, the use, and the nature of this explosive compound, are here placed in the foreground; as it is essential to the correct conception of the various matters hereafter to be explained, that the reader be first acquainted with the one grand principle in fire-arms, the propellant power of explosion.

Gunpowder, whether considered relatively to engines of war, or to those arms used with so much success in the sporting field, has, since its first introduction, been a source of much and frequent discussion. In regard to its origin, we shall not much enlarge, nor repeat the many suppositions and conjectures promulgated by the searchers after antiquarian evidence.

The inhabitants of India were unquestionably acquainted with its composition at an early date. Alexander is supposed to have avoided attacking the Oxydracea, a people dwelling between the Hyphasis and Ganges, from a report of their being possessed of supernatural means of defence: “For,” it is said, “they come not out to fight those who attack them, but those holy men, beloved by the gods, overthrow[19] their enemies with tempests and thunderbolts shot from their walls;” and, when the Egyptian Hercules and Bacchus overran India, they attacked these people, “but were repulsed with storms of thunderbolts and lightning hurled from above.” This is, no doubt, evidence of the use of gunpowder; but as it is unprofitable to investigate this subject further, we shall merely confine ourselves to the European authorities.

Many ascribe the discovery of gunpowder to Roger Bacon, the monk, who was born at Ilchester, in Somersetshire, in the year 1214, and is said to have died in 1285. No doubt he was by far the most illustrious, the best informed, and the most philosophical of all the alchemists. In the 6th chapter of his Epistles of the Secrets of Arts, the following passage occurs—“For sounds like thunder, and flashes like lightning, may be made in the air, and they may be rendered even more horrible than those of nature herself. A small quantity of matter, properly manufactured, and not larger than the human thumb, may be made to produce a horrible noise; and this may be done many ways, by which a city or an army may be destroyed, as was the case when Gideon and his men broke their pitchers and exhibited their lamps, fire issuing out of them with great force and noise, destroying an infinite number of the army of the Midianites.” And in the 11th chapter of the same epistle occurs the following passage:—“Mix together saltpetre with luru mone cap ubre, and sulphur, and you will make thunder and lightning, if you know the method of[20] mixing them.” Here all the ingredients of gunpowder are mentioned, except charcoal; which is, doubtless, concealed under the barbarous terms used; indeed, the anagram is easily converted into carbonum pulvere, with a little attention.

This discovery has also been attributed to Schwartz, a German monk, and the date of 1320 annexed to it; a date posterior to that which may be justly claimed for Friar Bacon; and as accident is stated to have been the means by which he discovered it, we have taken that incident as the subject of an illustration.

Mr. Hallam, referring to the authority of an Arabic author, infers that there is no question that the knowledge of gunpowder was introduced into Europe through the means of the Saracens, before the middle of the 13th century; and no doubt its use then was more for fireworks, than as an artillerist projectile force. There is good evidence, too, that the use of gunpowder was introduced into Spain by the Moors,[21] at least as early as the year 1343. Now, as Roger Bacon is known to have been an Arabic scholar, it is not at all unlikely that he might have become acquainted with the mode of making the composition, and also with its most remarkable properties, by perusing some Arabian writer with whom we are at present unacquainted.

This invention, by which the personal barbarity of war has certainly been diminished, is, when considered as a means of human destruction, by far the most powerful that skill has ever devised, or accident presented; acquiring, as experience shows us, a more sanguinary dominion in every succeeding age, and subserving all the progressive resources of science and civilization for the extermination of mankind: which, says Mr. Hallam, “appals us at the future prospects of the species, and makes us feel, perhaps, more than in any other instance, a difficulty in reconciling the mysterious dispensation with the benevolent order of Providence.”

The composition of gunpowder, as regards the proportions of the ingredients, has not undergone any material alteration; the chemical proportions of the ancients being nearly those of the present day.

Gunpowder is an explosive propellant compound, consisting of saltpetre or nitre, charcoal, and sulphur. The terms, explosive and propellant, are not here used as synonymous—they are not convertible; for a chemical mixture may possess the explosive power in a much higher degree than the propellant: fulminating gold, silver, and mercury, are dreadfully explosive;[22] but they have not the same projectile force, nor can they be used as a substitute for it. Several experiments have been made with compounds of this nature, but the result is the reverse of what might be expected. Nothing can resist the exceeding intensity of the action of fulminating powder; a shot, when fired in this way, is not projected as by gunpowder, but is split into fragments by the velocity of its explosion, as we shall hereafter have occasion to show.

Nitre, or saltpetre, is strictly the essence of gunpowder. It is a triple compound of oxygen, nitrogen, and potassium. The chemical action of those elements on each other, and the play of affinities between them at a high temperature, occasion the immense effect produced by gunpowder on the application of fire or heat. By universal consent, sulphur is included in the mixture, but it is not absolutely necessary for the “propellant power;” for nitre and charcoal only will generate effects similar to the compound with sulphur. Gunpowder made without sulphur has, however, several bad qualities; it is not, on the whole, so powerful, nor so regular in its action; it is also porous and friable, possessing neither firmness nor solidity. It cannot bear the friction of carriage, and in transport crumbles into dust. The use of sulphur, therefore, appears to be not only to complete the mechanical combination of the other ingredients, but being a perfectly combustible substance, it increases the general effect, augments the propellant power, and is thought to render the powder less susceptible of injury from atmospheric influence.

“There is one good reason,” says the Edinburgh Encyclopædia, “for the use of sulphur, although it does not contribute to the production of any elastic fluid. The carbonic acid which is generated would doubtless combine with the potash, if it were not for the presence of the sulphur, and thus so much elastic fluid would be lost. That this is the case we know to be true, from the fact that carbonate of potash is always formed when nitre is decomposed by charcoal alone, which I shall almost immediately show.” This certainly would be the case, to a certain extent, with gunpowder without sulphur—some carbonate of potash would be formed.

The sulphur, we have no doubt, from experiments we have made on this subject, is, in part, engaged during the explosion of gunpowder in expelling the sixth proportion of oxygen from the potash, so as to combine with the potassium, to form a true sulphuret of that metal. This fact is easily ascertained, from the circumstance that no sulphuretted hydrogen can be detected, by the most delicate tests, coming from the residuum left after firing gunpowder, until moisture has gained access to it. The bad smell which arises sometime after the burning of gunpowder, is occasioned by the decomposition of the moisture which the sulphuret of potassium attracts from the atmosphere; giving rise, by this decomposition and liberation, to the fœtid foul gas, called sulphuretted hydrogen, and the production of potassa, or the oxide of potassium.

A commission of French chemists and artillerists[24] was appointed by the Government, in the year 1794, to experiment upon the best proportions and constituents of gunpowder for the use of the French service. The following were the proportions of five different kinds prepared at the Essonne works:—

| No. | Nitre. | Charcoal. | Sulphur. | —— | |

|---|---|---|---|---|---|

| 1 | 76·00 | 14·00 | 10·00 | Powder of | Bâe. |

| 2 | 76·00 | 12·00 | 12·00 | „ | Grenelle. |

| 3 | 76·00 | 15·00 | 9·00 | „ | M. Morveau. |

| 4 | 77·32 | 13·44 | 9·24 | „ | Ditto. |

| 5 | 77·50 | 15·00 | 7·50 | „ | M. Keffault. |

The first and third, after 200 discharges with the proof mortar, were declared the strongest, and the third proportions were adopted at the recommendation of the commissioners. Some few years elapsed, and the first, owing to its better keeping quality, was substituted, as it contained less charcoal, and a little more sulphur. The French Government having always been extremely impressed with the value of durability in gunpowder, they have since returned to their ancient proportions: 75 nitre, 121⁄2 charcoal, 121⁄2 sulphur. The charcoal, the absorbent of moisture, being further reduced, and the sulphur, the preserving ingredient, being increased in the same ratio.

“Mr. Napier tried a small quantity made of nitre and charcoal only, and was much surprised to find it project a shot as far as the best powder made in the usual manner. It is found that, in small charges, sulphur is advantageous; but, in charges of several ounces, the projecting force is as great without as with it. Therefore, under certain circumstances,[25] sulphur may be dispensed with; but to make a good gunpowder, nitre and charcoal are indispensable.”

Amongst the brilliant discoveries of modern chemistry may be classed the development of the fact, that a chemical combination, to constitute the same compound, always takes place in definite and unalterable ratios. To select one example out of a multitude: one atom of carbon combining with two atoms of oxygen produces the gas; because more would answer no useful end. So, with reference to the sulphur, if it enter into combination only with the potassium—the base of the nitre—the sulphur should be in that proportion to form the sulphuret of that metal; and in this case there would be no superfluity, for that would only add to the weight of the charge of powder, and diminish its absolute and effective energy. The view of the case which we have taken supposes only two combinations, viz. carbon with oxygen, and sulphur with potassium. Should there be a more diversified play of affinities, and the several elements of the powder enter into more complicated action, accurate analysis would conduct us through all difficulties, and point out what the proportions of the ingredients ought to be in order to sustain that action, and to produce a perfect ultimate result.

We thus perceive how analysis bears upon the case. We can see by such reasoning on the subject, that, theoretically, there can be but one set of proportions calculated to produce the best and strongest gunpowder, and that those proportions must depend upon the established and unerring laws of nature. The[26] proportions, then, for gunpowder, by these considerations, will be those in which the carbon will just consume the oxygen of the nitre, and combine with the sulphur as much as will exactly saturate the potassium. This will be effected by an atom each of nitre and sulphur, and three atoms of carbon; or nitre 75·5, charcoal 18·8, and of sulphur 11·8.

In the present improved state of chemical science, when the nature of the bodies comprising gunpowder is so well known, as well as the compounds resulting from their action on each other, the proportions we have named may be taken as the best for practice.

The charcoal should, in particular, not be less than the nitre, as the smallest portion less than the whole atom would be the same as to leave out the whole atom, in which case there would be no carbonic oxide formed. If, for example, instead of the proportions of nitre 75·5, charcoal 16·2, sulphur 15, the carbon were 16, then there would be 4·2 of carbon left in the residuum, and no carbonic oxide would be formed, since bodies cannot unite but in definite proportions.

From these considerations we can perceive the reason why a small proportion of carbonic oxide is always formed during the decomposition of nitre by charcoal; for it will be evident, that as the nitric acid contains five atoms of oxygen, four of these must combine with two atoms of carbon to form two atoms of carbonic acid, while the odd atom of oxygen is compelled to take another atom to form carbonic oxide. But this is not the case in the combustion of[27] gunpowder, as carbonic acid and nitrogen are the principal gases generated.

These proportions differ from any other formula yet prescribed; and, though different in a great degree from the proportions laid down by various writers on the subject, the reasons which are here given, as has been seen, are such as carry with them a conviction of their truth: for there cannot possibly be any benefit arising from a greater quantity of any of these materials than is absolutely necessary to form the composition in question; and if the smallest quantity be above what is requisite to consume the whole, that, however small it may be, is highly detrimental to the effective energy of the mass. What we may here call clean gunpowder, such as may be used with confidence for repeated discharges of fire-arms of any description, is of the greatest importance; therefore, it does not appear to us, that any given proportions are so likely to accomplish that object as those before specified.

TABLE OF COMPOSITION OF DIFFERENT GUNPOWDERS.

| Mills. | Nitre. | Charcoal. | Sulphur. |

|---|---|---|---|

| Royal Waltham Abbey | 75·00 | 15·00 | 10·00 |

| France, National Mills | 75·00 | 12·50 | 12·50 |

| French Sporting | 78·00 | 12·00 | 10·00 |

| French Mining | 65·00 | 15·00 | 20·00 |

| U. S. of America | 75·00 | 12·50 | 12·50 |

| Prussia | 75·00 | 13·50 | 11·50 |

| Russia | 73·78 | 13·59 | 12·63 |

| Austria (Musket) | 72·00 | 17·00 | 16·00 |

| Spain | 76·47 | 10·78 | 12·75 |

| Sweden | 76·00 | 15·00 | 9·00 |

| Switzerland (Round Powder) | 76·00 | 14·00 | 10·00 |

| Chinese | 75·00 | 14·40 | 9·90 |

| Theoretical proportions as above | 75·00 | 13·23 | 11·77 |

Gunpowder consists of a very intricate mixture of sulphur, carbon (charcoal), and nitrate of potash (nitre).

The proportions in which they exist are one equivalent of nitre, one of sulphur, and three of carbon. The great explosive power of gunpowder is due to the sudden development from its solid constituents of a large quantity of gases; these gases are nitrogen and carbonic acid.

At the ordinary temperature of the atmosphere these gases would occupy a space three hundred times greater than the bulk of the gunpowder used; but owing to the intense heat developed at the moment of explosion, the gases occupy at least 1,500 times the bulk of the original gunpowder. The mixture, consisting of one equivalent of nitre, one of sulphur, and three of carbon, would yield three equivalents of carbonic acid, one of nitrogen, and one of sulphuret of potassium. The change may be represented thus,—

S + C₃ + KONO₅ = 3 CO₂ + N + KS.

The only solid residue, therefore, is the sulphuret of potassium, and this is the compound which produces the sulphurous odour on washing out a gun barrel; water is decomposed, sulphuretted hydrogen and potash being the result of the decomposition.

Now supposing the elements of gunpowder to exist in these proportions, it is essential, in order to secure their perfect combination, and thus to produce the[29] largest possible volume of gas, that the elements should be in the most minute state of subdivision. Chemical action is a force exerted at insensible distances only, and chemical substances having the greatest affinity for each other will not combine, unless their elements are brought into immediate contact: thus oxygen and hydrogen may be mixed together in the exact proportions to form water; but no chemical combination will occur, simply because the ultimate particles of the two gases are not sufficiently near to each other for their chemical affinities to be brought into play; if, however, these gases are subjected to very strong pressure, so as to bring their particles into immediate contact, combination occurs, and the production of water is the result.

In order to insure the perfect combination of the elements of gunpowder the same conditions are necessary; that is to say, the ultimate particles of the nitre, charcoal, and sulphur, must be brought into the most direct contact, or the explosive power of the gunpowder will be comparatively trifling. If, for instance, the nitre, charcoal, and sulphur be pounded in a mortar, no explosion but a slow combustion will occur when the mixture is ignited; so that unless this intimate mixture of the elements is carefully attended to in the manufacture of gunpowder, it is easy to see that the article produced will be of comparatively little value.

It is evident then that if tons of the elements of gunpowder were stored in a warehouse which accidentally[30] caught fire, no explosion would occur from the formation of gunpowder; though its ingredients would greatly increase the rapidity of combustion.

This remark is elicited by the recollection of a fearful explosion which took place at Gateshead in 1854.

It may be remembered that a warehouse caught fire from an adjoining mill, and the explosion was supposed to have been produced by the ignition of the elements of gunpowder stored in the warehouse in a crude state. The upper story of the building contained a large quantity of crude sulphur, and the basement story about the same quantity of nitre, whilst chemicals of various kinds were stored in other parts of the building; but according to the accounts published there was no large quantity of carbon in the warehouse; nevertheless, a terrific explosion took place, and after a lengthened investigation, the conclusion arrived at was this: the sulphur melting, mixed with the nitre, gunpowder was thus formed, and igniting, exploded, producing the terrible effects.

But gunpowder may be made without sulphur, whereas gunpowder without carbon is an impossibility; and though the elements of gunpowder had all been present, no explosion could have occurred, unless they had become mixed in the intimate manner already described.

It is true some of the chemical substances in the warehouse might have produced a fearful explosion: but a more plausible explanation is to be found in the[31] fact, that gunpowder was at that time much more valuable abroad than at home; and it is quite possible that some kegs of gunpowder might have been stored away in this warehouse, until a convenient opportunity presented itself for their removal.

The foregoing remarks will serve to explain how it is that powder varies so much in strength and quickness of fire. If the elements are imperfectly incorporated, the powder can never be equal to that which is properly made; and the manufacturer, having ascertained the best proportions in which to mix the elements, had better improve his machinery for incorporating them, rather than his knowledge of the chemistry of gunpowder. These observations will also serve to explain the apparent anomaly, that the French, and some of our other continental brethren, are held to produce a much inferior sporting gunpowder to that which is manufactured in old England.

Gunpowder is now made by all the sporting gunpowder manufacturers from No. 1 to No. 5 grain; and it appears certain that a further increase in the size of the grain would be advantageous; for many years of patient and laborious experiment clearly show, that the old notion of gunpowder being blown out of an ordinary sized gun in an unburnt state, is one of the “purest of vulgar errors:” such a thing indeed cannot possibly happen unless the powder be bad, or the gun imperfectly made, or injudiciously charged.

I am satisfied that I am under rather than over estimate, when I assert that six drams of ordinary[32] sporting gunpowder may be beneficially and completely exploded in a barrel of 14 bore, 2 feet 6 inches long, with a resisting projectile one ounce in weight above it. This, however, being more than a double charge for such a gun, cannot be pleasantly practised; and it is only asserted by way of argument.

Assuming, then, for argument’s sake, that six drams of gunpowder are exactly consumed in passing from the breech to the muzzle of a gun 2 feet 6 inches long, and that the shot, therefore, acquires its greatest velocity as it leaves the muzzle, it follows that the ordinary charge of 21⁄2 drams will be wholly consumed before it has traversed half the length of the barrel, and consequently the charge of shot must here acquire its greatest velocity. It is certain, then, that the shot must travel the latter half of the barrel at a diminished velocity, and its velocity must continue to diminish as it passes up the barrel; for two obvious reasons—1st, The column of air in front of the charge is more condensed, and thus offers a greater resistance to the exit of the charge; 2nd, The velocity is continually diminished by the increased friction of the charge against the barrel.

The perfection of projectile science is to make the projectile acquire its greatest velocity at the instant of leaving the muzzle; and if, by increasing the size of the grain of gunpowder, we can diminish the rapidity of its explosion—thus causing it to burn and generate fresh gas up to the muzzle of the gun—the projectile will then acquire its greatest velocity, and leave the gun to the best advantage: this is the[33] important point which has hitherto been overlooked, not only in fowling-pieces, but in the expansive principle of rifles.

For artillery practice of every kind, whatever the weight of the projectile, gunpowder of a granulation suited to the weight of that projectile is essential, if we would produce the greatest possible effect by the least expenditure of means.

In artillery, at this most important time in war’s history, no attention whatever is paid to this essential principle. A long 10-inch gun, a 68-pounder, and a short 6-pounder are all charged with powder of the same granulation; whilst by a more judicious use of gunpowder of suitable granulation, the range might be extended, just as it is in sporting arms, to nearly 20 per cent.

Artillerists seek to effect great range by doubling the weight of the gun, and projectile monsters meet us at all points, to become in every case “monster failures.”

I fear that the most important points have been entirely lost sight of. Instead of ascertaining whether we have suited the projectile power to the 8-inch or 56-pounder, so as to get work from it which is now done by the 10-inch, we have, in our anxiety to get range, looked only to the form or material of the gun; vital principles being totally excluded. The construction of the gun being perfect, the question is, can the expellant force be brought to an equal state of perfection?

In order to obtain the best results from a gun, the[34] gun itself must be perfect in construction, and the expellant force must be brought to bear in the best possible manner upon the projectile; and this is to be done by attending to the granulation of the powder, which must be suited to the length of the gun, to its bore, and to the weight of the projectile.

Common-sense, engineering skill, will demonstrate, that according to the weight of matter to be projected must be the nature of the expellant; accumulative—until it has overcome the inertia of that matter, accelerative—until it has communicated to it the highest state of velocity its power is capable of effecting. If, on the other hand, it is inferior to this, science has not extracted from it the full horse-power it contains; and we are uselessly expending force and destroying our engines by undue pressure being exerted on one part, and inferior pressure on another; whilst by a proper distribution of that force, durability of the cannon is insured, and from twenty-five to thirty per cent. more work may be obtained from an equal quantity of powder, provided its granulation be judiciously selected according to the area of the gun.

There is abundant proof that on this engineering question we have hitherto worked by the “rule of thumb;” prejudice having been a stumbling-block, which nothing but stern necessity will remove. The authorities have but just discovered this, although their attention was directed to it several years ago. In the year 1852, I produced before the Small Arms Committee, at Enfield, a portion of gunpowder suited[35] to the expansive rifle; it was tried to a limited extent, and dismissed with the remark, “We don’t think there is much in it.” Experience, however, has demonstrated the truth of my observations, for, in all extreme range shooting with the expansive or “Greenerian”-principled rifles, not only is considerably greater accuracy obtained with it, but an increase of range equivalent to fifteen or twenty per cent.

Another advantage of using gunpowder of a suitable granulation is the absence of sharp recoil; and thus greater accuracy of range is obtained—accuracy of range and steadiness of weapon being inseparable.

Large-grain gunpowder is not only a more effectual expellant than the fine grain, but is much more safe to use, for by using it the risk of bursting the barrel is much lessened; as a very simple illustration will show. If we estimate the force generated by the usual charge of 21⁄2 drachms (I confine the question to the 14-bore gun, for uniformity) to be 5,000 lbs., whether the powder be fine or coarse grain, it follows that the fine powder, igniting so rapidly, will exert all its force on the breech end of the gun; whereas the coarse powder, igniting less rapidly, distributes this force over the whole length of the barrel: hence the greater risk of a gun bursting with fine powder than with coarse. If we suppose the fine powder to be entirely ignited when it reaches half way up the barrel, then the force of 5,000 lbs. is exerted on the lower half of the barrel; but if the coarser grain is not entirely ignited until it reaches[36] the muzzle, then the force of 5,000 lbs. will be distributed over the whole length of the gun.

But this is not all. The fine powder, igniting almost instantaneously, exerts its force in all directions at once, and the barrel may burst at the side before the charge has time to move; whereas the coarse powder, igniting as it does more slowly, first lifts the charge, and then the volume of gas behind it increasing as the powder becomes more thoroughly ignited, sweeps the charge out of the barrel with a velocity increasing towards the muzzle.

If time is not given for the charge to receive the full advantage of the expansive force of the generated air, the force is exerted, not upon the charge, but upon the barrel of the gun itself; and that time is necessary for the full development of this force, is proved by the fact that miners mix their gunpowder with sawdust, in order to diminish the rapidity of its explosion and thus get the advantage of its force in the distance: from the miners, then, let us learn how to obtain the greatest benefit from this force, and waste it not.

There can be no doubt of the importance of this principle; little progress has, however, been effected from want of scientific illustration; let it be defined like that of steam power, and its adoption will follow as a natural consequence.

For several years I have had gunpowder manufactured of various sizes, at the sight of which most sportsmen would express their astonishment.

One objection held by sportsmen to the large[37] grained gunpowder is that it does not come up the nipple of the gun; now although I do not consider this at all important, still if the specific gravity of the gunpowder were increased by compressing 11⁄2, 2, or 3 grains of gunpowder into the space of 1 grain, by means of hydraulic pressure, this objection would at once be obviated; whilst at the same time, the powder would be less liable to absorb moisture, or to become friable with age: either of which conditions is incompatible with good shooting.

The granulating of gunpowder, to be of the greatest benefit, should be on a uniform principle; the manipulation should be alike in all particulars, but especially in that part of the process which determines the specific gravity. The hydraulic pressure on the cake should be alike in all cases: in fact, the various sizes of grain might be produced from the same cake, and the desired object be thus obtained. But so long as the practice is followed of producing large grain from less condensed cake, the article produced will give unsatisfactory results; and the advantages which might be attained, as my experience denotes, and which would be of the greatest service, alike in sporting, rifle, and artillery powder, will be nullified.

Great improvements are yet to be made, especially in the powder used for artillery; whilst range, accuracy, and lessened recoils are points which may be determined with almost mathematical precision.

Great fame is in prospect for any one who can grasp and handle well this granulation principle; especially if he can define the sizes to be used for[38] different varieties of guns. Artillerists who contend that a medium size grain, to suit all sizes of gun, is advantageous, might as well contend that cannon of a medium size would be preferable to so many different sizes, because, though we lose in range, accuracy, and recoil, it would be more convenient to have but one sized gun.

In making large grained gunpowder, the manufacturers defeat one of the main objects to be gained by granulation, from not subjecting it to the same amount of pressure which is necessary for the granulation of the very fine grain. In granulating very fine powder, it is necessary to subject the cake to such an amount of hydraulic pressure as shall give the mass a marble-like structure, or during the process of granulation, the whole of it crumbles into dust; but the coarser gunpowder may be granulated without subjecting it to this high degree of pressure, hence each grain is more porous and of lesser specific gravity: a difference which it is most important to avoid. It is clear, therefore, that according to the present mode of manufacturing gunpowder, the large and the fine grain are of very different kinds; the main difference being in their specific gravities. Gunpowder of less density burns with greater rapidity, because it is more open and porous; and if uniform density was observed, the diversity in the size of the grain need not be so great; whilst, at the same time, this anomaly might be avoided—that the same measure of fine and large-grained gunpowder contains a difference of the expansive element amounting to fifteen or[39] twenty per cent. As gunpowder is now manufactured, it is highly necessary in all comparative trials to weigh, and not to measure the charge, or the results will be deceptive and worthless. The granulation question struggles with undeserved difficulty. Gunmakers, either not understanding the question, or constructing the chambers of their guns improperly, and not using suitable nipples, decry the adoption of large-grained gunpowder; but they forget the increased range obtained in the killing from their guns, and the éclât a long shot produces. In trials of guns at thirty or forty yards, the difference in the shooting with fine and large-grained gunpowder is not so apparent, and the maker exclaims, “Oh! the fine powder shoots stronger, and as close as the coarse.” I admit this to be the case, at short distances; but the great advantage of using the large grain is sufficiently evident when shooting at forty-five, fifty, and sixty yards, for then the fine grain entirely fails: simply from the oft-repeated fact, that the fine powder is more of a propulsive, while the large grain is an expellant force; so that according to the law of resistance in aëriform fluids, the one is sooner reduced to medium velocity than the other, which exerts its action more evenly. Powder of larger grain is thus more suitable for the larger sizes of shot, and would give an increased range in usual shooting, for the shot is kept better together, and is projected to greater distances. A common way of testing the quality of gunpowder is, to rub it between the hands, and observe the darkness of the stain; the darker[40] the stain the more inferior the gunpowder is held to be. This test is, however, decidedly fallacious, because the gunpowder may be of low specific gravity, or it may have become friable from age and other causes.

Whales are shot with gunpowder proportioned to the weight of the harpoon required to kill them. Duck guns of the largest calibre are comparatively useless unless the gunpowder used is granulated according to the weight of the projectile; and the same law holds in regard to the most “mammoth” engine yet to be devised by the mind of man.